ERP ZEROFORCE

Manufacturing Management

The Manufacturing module in ERP ZEROFORCE covers all necessary features a Manufacturing business would need. There are options to take a Work Order, enter stock of items, create a Production Plan, create a Downtime Entry, manage the Bill of Materials for Finished Goods / Template Items, generate reports, and more. Integrate your production planning and shop floor. ERP ZEROFORCE’s customer management, sales orders, inventory, purchasing, accounting, and financial reporting make real-time coordination across all your business verticals easier.

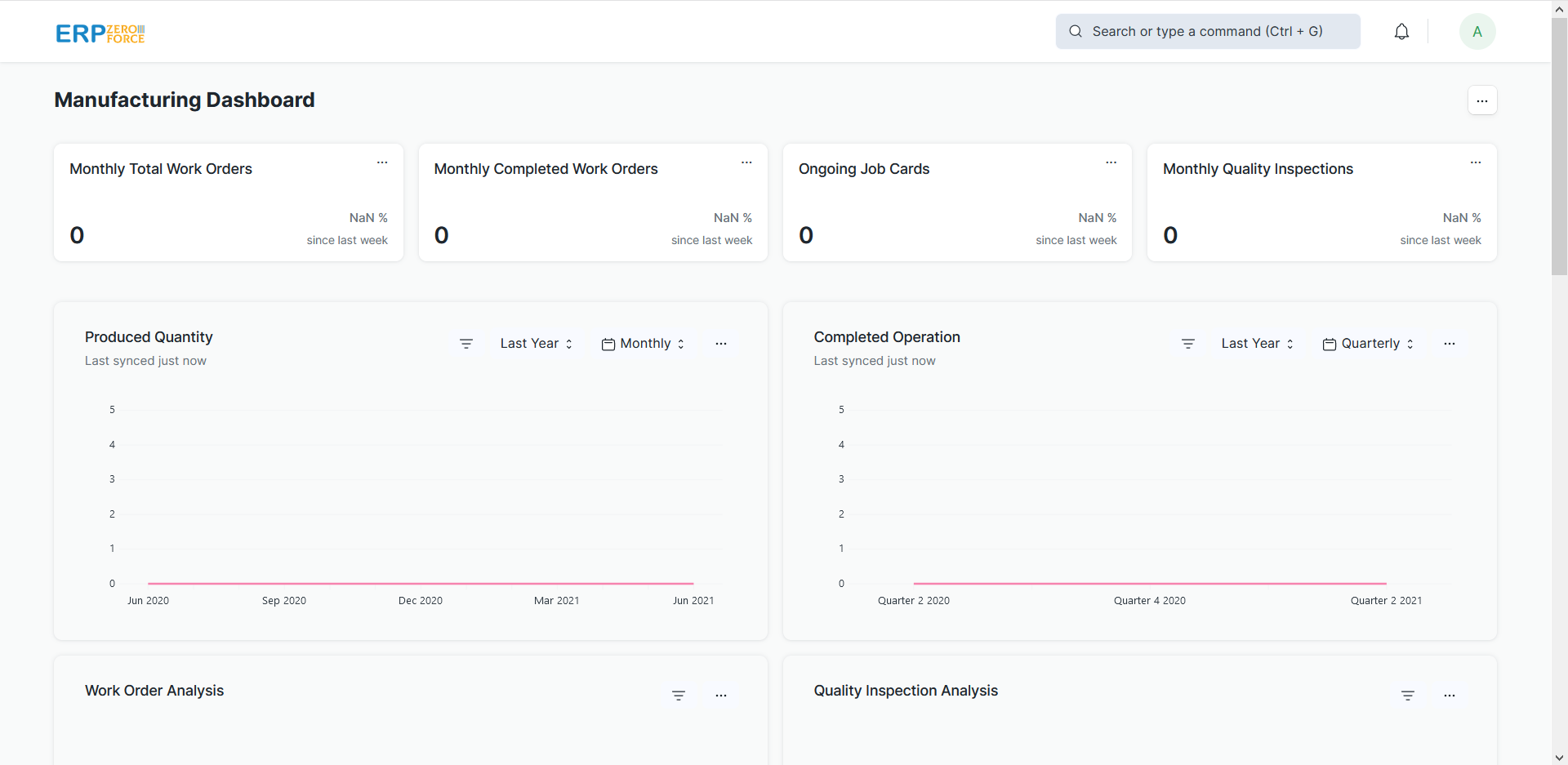

Manufacturing Dashboard

Number Cards

1. Monthly Total Work Order: – You will get the total count of Work Orders which are in Open, In Progress, and Completed state. The Work Orders created one month before the current date will be displayed in the number card.

2. Monthly Completed Work Order: – The user will get the total count of Work Orders which are in the Completed state. The Work Orders created one month before the current date will be displayed in the number card.

3. Ongoing Job Card: – he user will get the total count of Job Cards that are not in the Completed state.

4. Monthly Quality Inspection: – The user will get the total count of Quality Inspection records which are in the Submitted state. The Work Orders created one month before the current date will be displayed in the number card.

Dashboard

Produced Quantity

The chart will give the information about the total quantity produced (using Work Order) in the last year on a Quarterly basis. Users can also view the chart data based on Daily, Weekly, Monthly, Yearly basis.

Completed Operation

The chart will give information about the total number of operations completed in the last year on Quarterly basis. Users can also view the chart data based on Daily, Weekly, Monthly, Yearly basis.

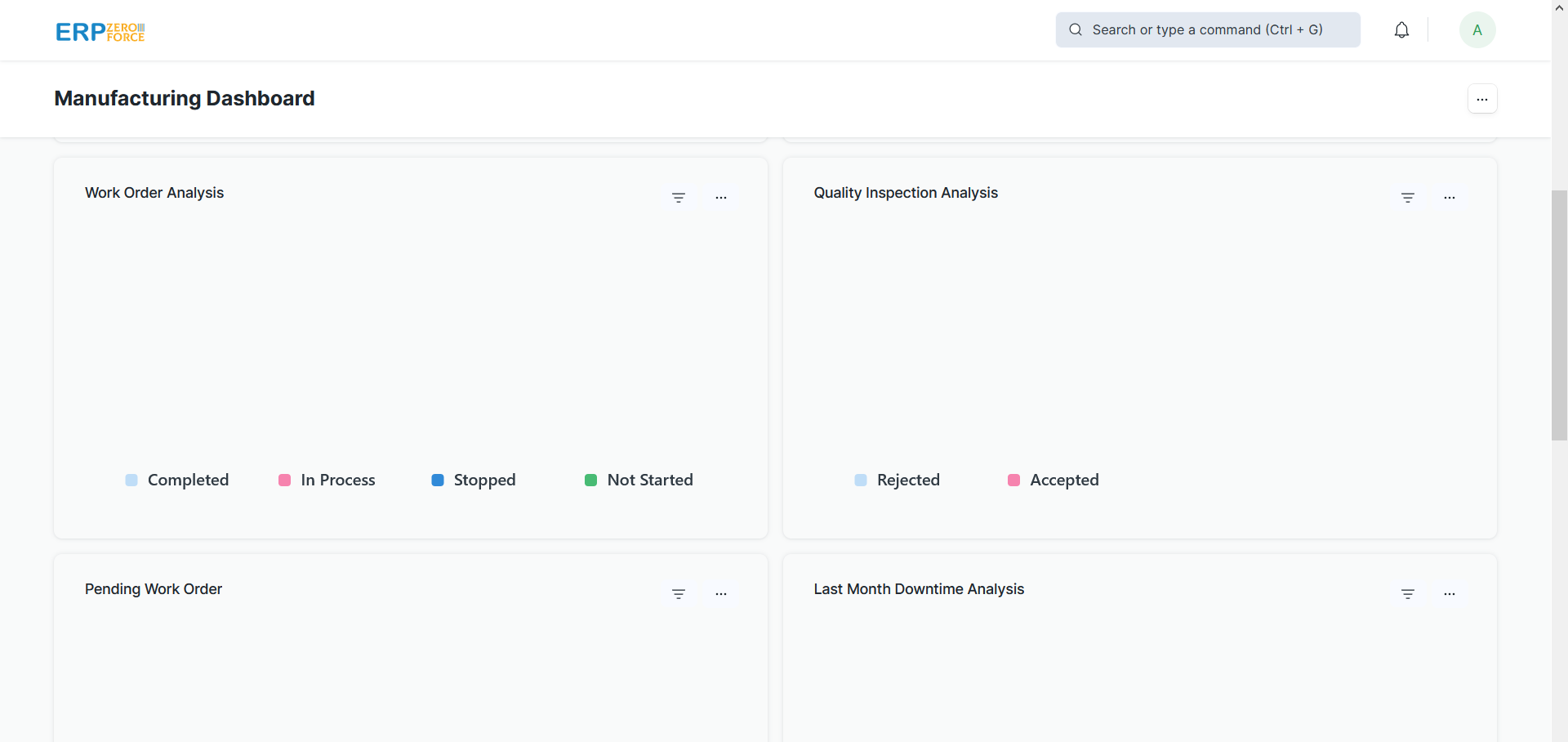

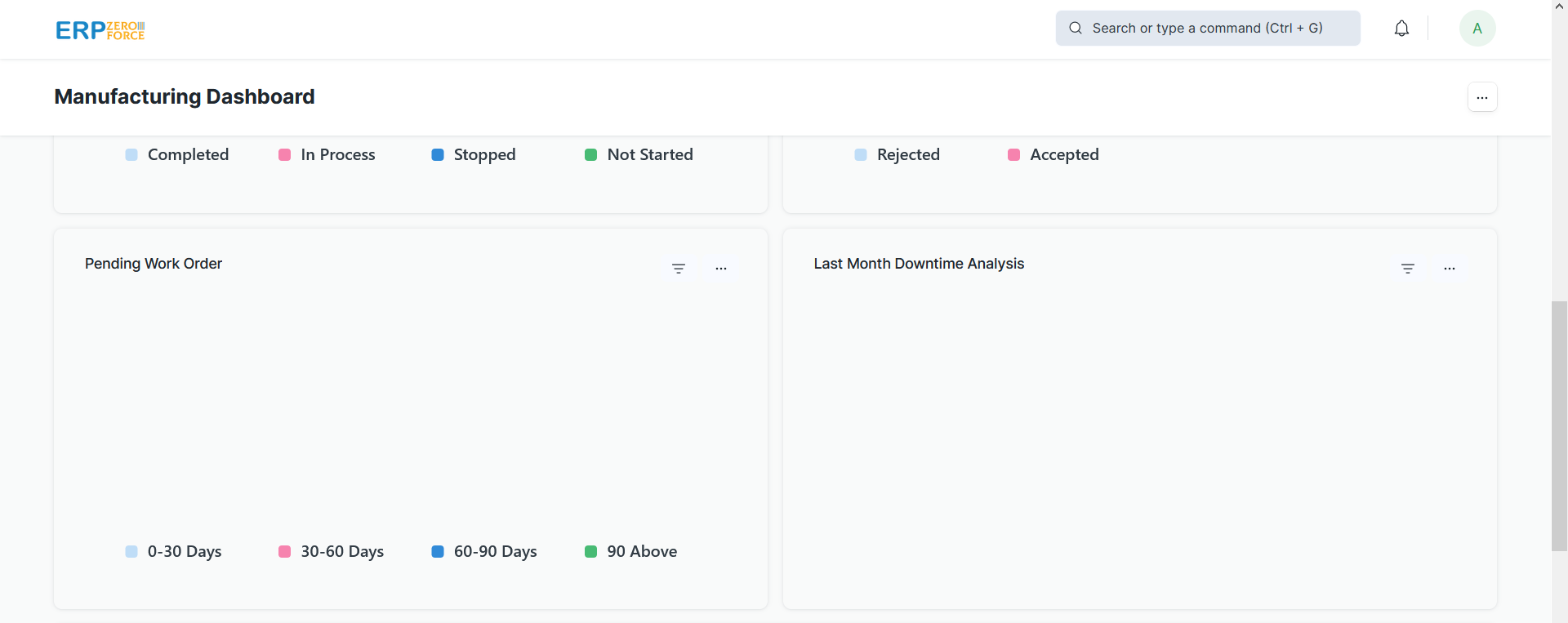

Work Order Analysis

This chart will give the information about the number of Work Orders based on Not Started, In Process, Stopped, Completed statuses. This Donut chart will provide the information based on the last year’s Work Order data. Your can also change the date range by clicking on the Filter button.

Quality Inspection Analysis

This chart will give information about the number of Quality Inspections based on Accepted and Rejected status. The chart type is a donut and it will provide the information based on the last year’s quality inspection data. Your can change the date range by clicking on the Filter button.

Pending Work Orders

The chart will give information about the number of Work Orders that are pending based on the aging days. The number of aging days is calculated based on the difference between the current date and planned start / actual start date days.

Last Month Downtime Analysis

The chart will give information about the total number of minutes a machine was not working in the last month. This helps the operator to know which machine has not performed well and requires maintenance.

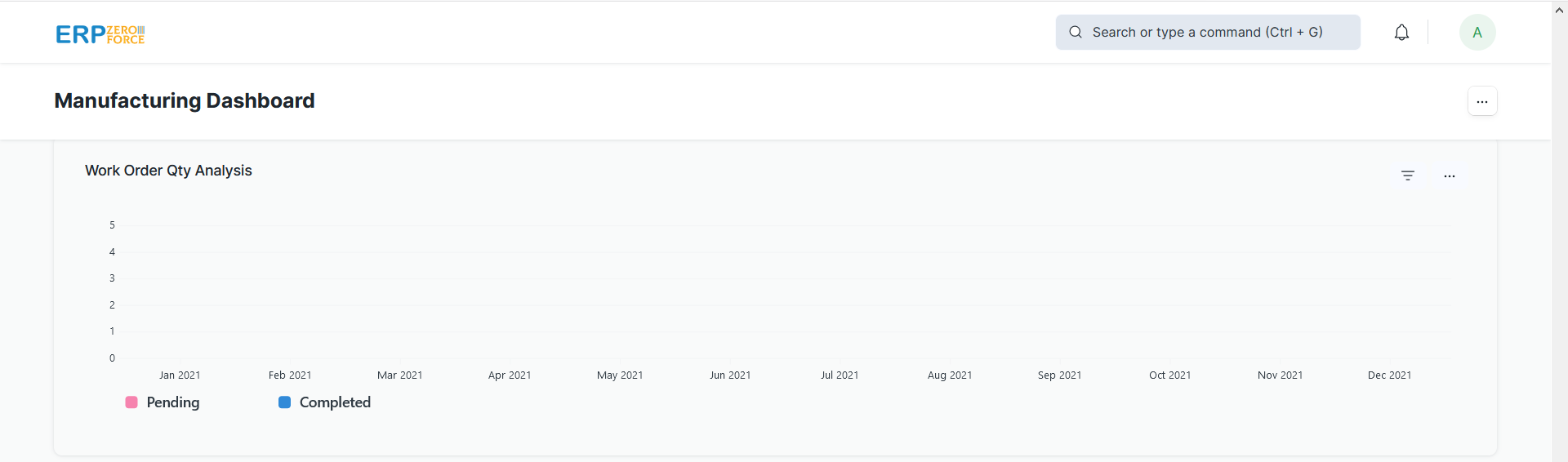

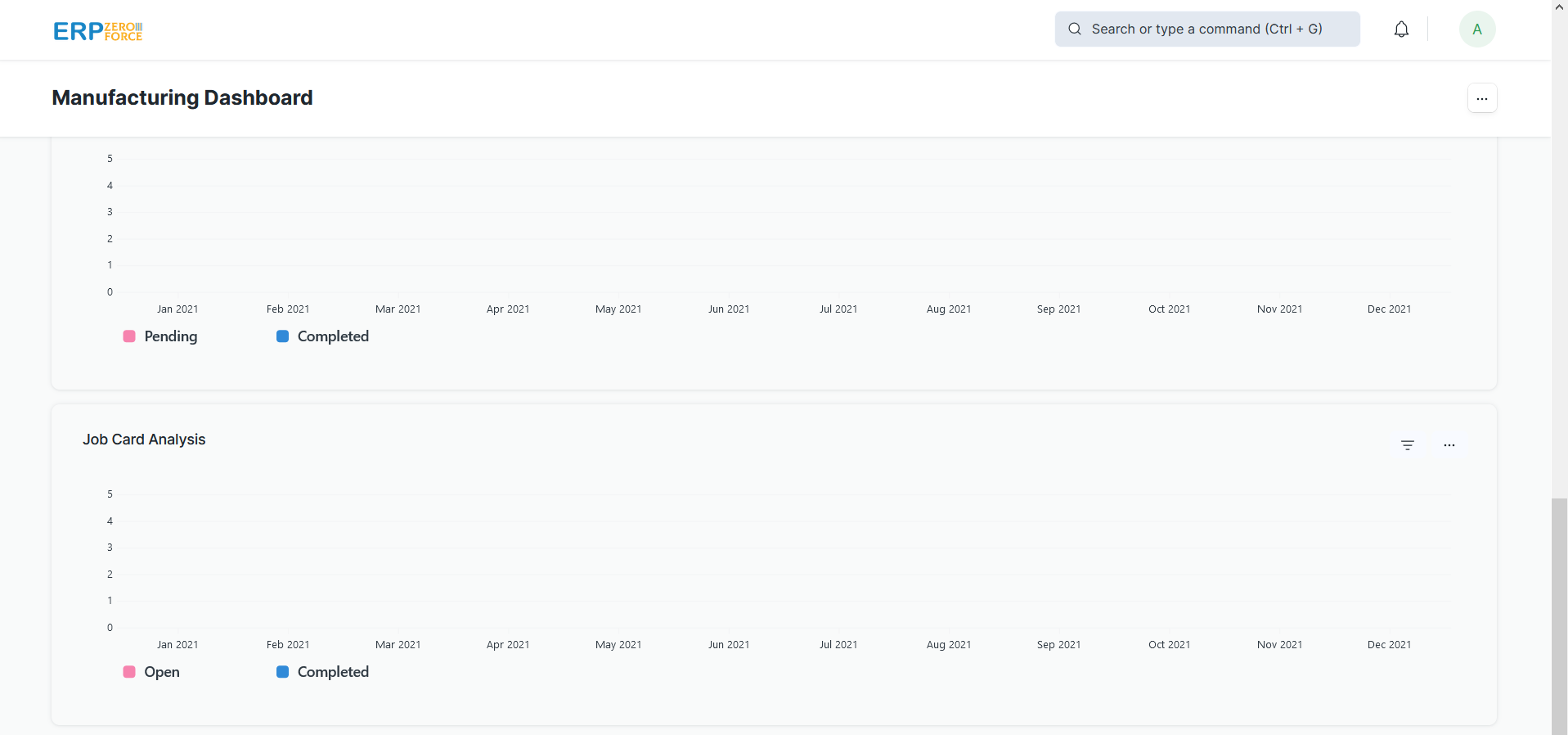

Work Order Quantity Analysis

The chart will give information about the total number of quantities that are Pending and Completed based on the Work Orders every month for the last year.

Job Card Analysis

The chart will give information about the total number of Job Cards which are in the Pending and Completed states every month for the last year.

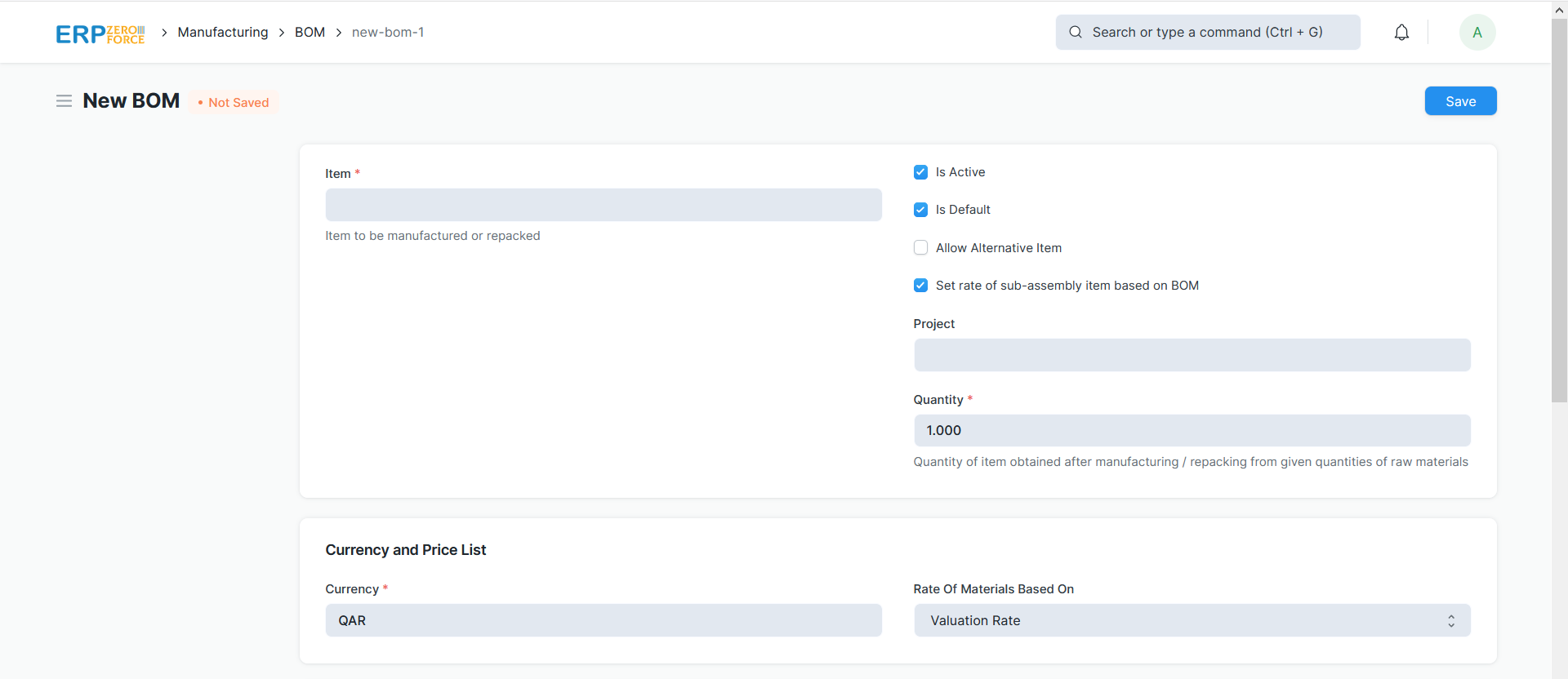

Bill of Material (BOM)

Shop floor management

Subcontracting

Item variants

Batched inventory

Serialized inventory

Material resource planning

Capacity planning

Multiple units of measure

Quick stock balance

Stock replenishment